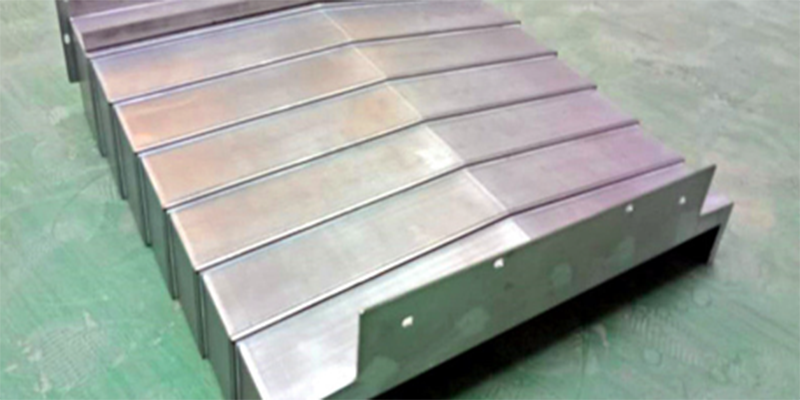

The steel plate protective cover is a protective cover with good sealing, which can prevent iron chips, coolant and accidental accidents of tools. The steel telescopic guide rail protective cover is a traditional protection form for machine tools. Through certain structural measures and suitable chip plates, the penetration of coolant can also be effectively reduced.

Steel telescopic rail guards can adapt to the ever-increasing requirements of modern machine tools for high technology, installation location, high operating speed, etc.

There are mainly the following types of steel plate guards for special purposes:

1. High-security steel plate guards:

This type of guard is generally also called armored steel plate steel plate guard. This product is suitable for installation in prisons or other places that are easily damaged. It is made of 0.134-inch thick No. 10 welded steel, and the window material is 1/2-inch thick, anti-wear treated polycarbonate. It can withstand impact and attack, has bulletproof and puncture-proof characteristics, and is suitable for places that require high security, such as monitoring rooms, banks, etc.

2. High dustproof steel plate guard:

It has good sealing performance, can effectively prevent dust, particles, etc. from entering the equipment, protect the normal operation of the equipment, and is suitable for dusty environments, such as factory workshops, construction sites, etc.

3. High temperature steel plate protective cover:

High temperature steel plate protective cover refers to the steel plate protective cover that protects the normal operation of the camera and lens when the camera is used in an environment greater than 40℃ and natural convection and radiation heat exchange cannot reach the normal operating temperature. It adopts special cooling methods, such as air cooling system, water cooling system, eddy current cooling, etc. It is suitable for high temperature working environments, such as steelmaking furnaces, heating furnaces, etc.

4. Explosion-proof steel plate protective cover:

It has explosion-proof performance and can protect the safety of equipment and personnel in explosive hazardous environments. It is suitable for hazardous places such as chemical plants and oil fields. It must comply with the safety regulations of explosion-proof and dust explosion-proof electrical equipment. The materials used are the same as the pan/tilt head, usually thick-walled all-aluminum structure or stainless steel structure. The diameter is generally 6", 8", 10", etc., and the lead-in wire interface is equipped with explosion-proof seals.

5. Anti-corrosion steel plate protective cover:

It has anti-corrosion properties and can resist the erosion of corrosive substances such as acids and alkalis. It is suitable for chemical plants, marine environments and other places with strong corrosiveness.

In short, the machine tool steel plate protective cover is an important equipment component, and its design and manufacturing need to meet multiple requirements and quality standards. Multiple factors need to be considered in the design and manufacturing process, including material selection, structural design, manufacturing process, etc. Only by strictly controlling the quality and precision of each link can high-quality and high-performance machine tool steel plate protective cover products be manufactured.

© 2012‐2022 SHANGHAI PUXIONG, Inc. All rights reserved. ProPureX™