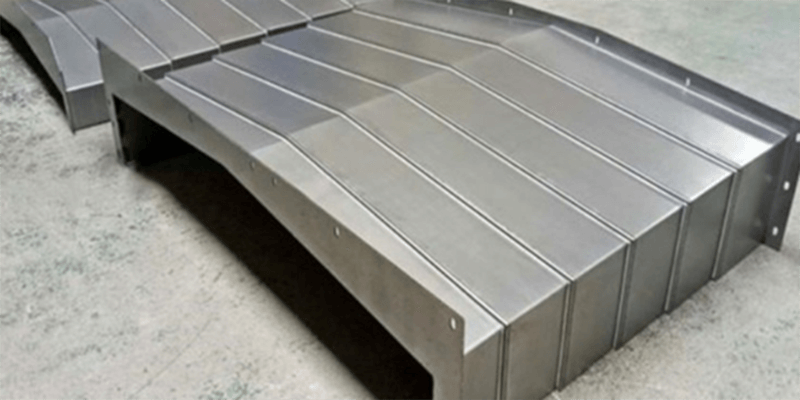

Steel telescopic guide rail guards are a traditional form of machine tool protection. In this field, steel telescopic guide rail guards are widely used, which play an effective protective role in preventing the entry of chips and other sharp objects. Through certain structural measures and appropriate chip plates, the penetration of coolant can also be effectively reduced.

The machine tool steel plate guard is a component of the machine tool, which can be divided into inner and outer guards. The outer guard of the machine tool covers the entire machine tool and is mainly used to protect the operator. The inner guard of the machine tool is mainly used to protect the surface of the machine tool and its parts from external corrosion and damage.

The steel plate protective cover has the characteristics of good sealing and anti-chip, which brings better effect to the use of machine tools. The distance between the guide surface of the mechanical equipment and the steel plate protective cover is 5mm at the minimum and 10mm at the maximum. The steel plate protective cover is widely used in the field, which plays an effective protective role in preventing the entry of chips and other sharp objects. Through certain structural measures and suitable scraper plates, the penetration of coolant can also be effectively reduced.

The number of sections of the steel telescopic guide rail protective cover is very important for its proportion, weight and operating characteristics. Each single section should be as long as possible, so as to reduce the number of sections and reduce costs. Generally, the maximum stretching and minimum compression ratio should be between 3:1 and 5:1.

The steel plate protective cover sheet is generally made of cold-rolled sheet with good surface quality. After the sheet metal parts are unfolded, their size must be smaller than the sheet size, and it is important that the sheet area welding is not required.

The CNC machine tool protective cover is usually completed by using some CNC sheet metal equipment in conjunction with some manual operations. When it comes to the size of the processing, the first thing to consider is the processing capacity of the entire equipment. Only in this way can we avoid errors in processing due to the size of the parts exceeding the processing capacity of the equipment.

© 2012‐2022 SHANGHAI PUXIONG, Inc. All rights reserved. ProPureX™