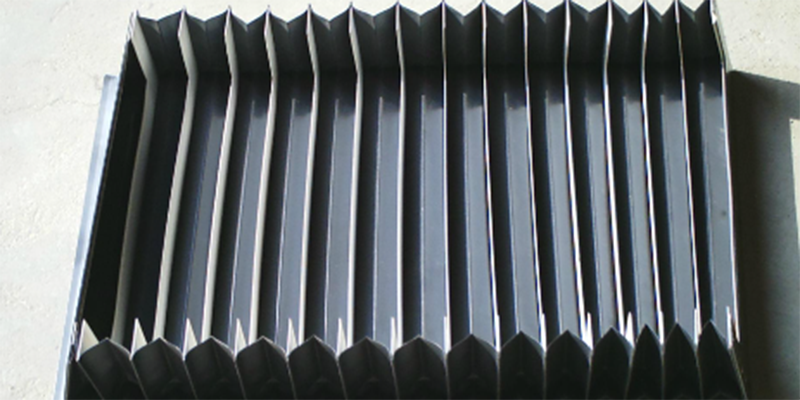

There are many types of protective covers, and they are used in many aspects of life. The protective cover can strictly prevent dust, chips, hard sand, etc. from entering the track, reduce the damage of hard granular foreign matter to the sliding rail surface, reduce the influence of the guide rail deformation on the processing accuracy due to operation, and maintain the processing accuracy of the machine tool.

1. Improper operation

1. Impacting the protective cover: When the tool contacts the workpiece, if it has impacted the protective cover before contact, it may cause the protective cover to deform.

2. Twisting and deformation. When the processing power of the machine tool is large or the length of the workpiece is different, the worker may extend part of the workpiece out of the range of the protective cover, which will cause the protective cover to twist and deform.

2. Poor material

The materials of the protective cover are usually divided into organic glass and hard polyurethane. The former has the characteristics of high transparency, UV resistance and impact resistance, while the latter is harder and tougher. However, if the material is not good, it will also cause damage to the protective cover.

2.1. The quality of organic glass material is poor and cracks appear.

2.2. The hard polyurethane material is not strong enough and is easy to deform.

In order to ensure the stability and durability of the protective cover, it is necessary to pay attention to the selection of materials and the optimization of design schemes, and to perform regular maintenance. The protective cover is a common safety equipment. Its main function is to protect workers or operators from harmful substances, prevent accidents, and ensure production safety. Protective covers are widely used in many fields and are a very important safety measure.

© 2012‐2022 SHANGHAI PUXIONG, Inc. All rights reserved. ProPureX™