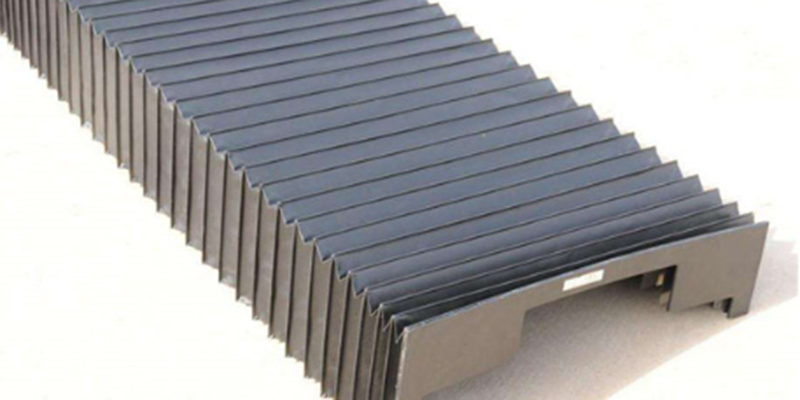

1. The role of the accordion cover

The accordion protective cover is usually composed of PVC frame, environmentally friendly three-proof cloth and high-frequency heat sealing, and has dust-proof, oil-resistant, high-temperature resistant and other properties. It is widely used in machine tools, automation equipment, automobile production assembly lines, medicine, measurement, automatic control and food technology. In addition, the accordion protective cover also has the characteristics of long stroke and small compression, which can effectively prevent dust, iron filings and other debris from entering the machine tool in various working environments, and improve the overall value and aesthetics of the machine tool.

2. Design principles

When designing an organ cover, some basic principles need to be followed, such as conforming to aerodynamic principles, aesthetic appearance, corrosion-resistant materials, strong structure, and easy use. In addition, attention should be paid to preventing water accumulation and fire prevention.

3. Material selection

Different materials have differences in strength, corrosion resistance, sound insulation, transparency, etc., so they should be selected according to actual needs. 1. Good corrosion resistance: Since the organ protective cover is often exposed to moisture and pollutants in the air, materials with good corrosion resistance, such as stainless steel and aluminum alloy, should be selected.

3.1. High strength: The organ protective cover needs to have sufficient strength to resist external impact and wind force, so the strength of the material must meet the design requirements.

3.2. High transparency: The organ protective cover needs to fully display the internal equipment, so the material should be selected with high transparency.

Application field

The organ protective cover is a device used to protect the safety of machines, equipment and staff. Its application range is very wide, mainly including the following aspects:

1. Mechanical processing industry: such as protective covers of mechanical equipment such as drilling machines, planers, milling machines, grinders, shearing machines, etc.

2. Electronic manufacturing industry: such as protective covers of equipment such as printed circuit board production, placement machines, welding robots, etc.

3. Chemical industry: such as protective covers of equipment such as mixing tanks, reactors, centrifuges, etc.

4. Automated production lines: such as protective covers of equipment such as robot production lines and packaging production lines.

© 2012‐2022 SHANGHAI PUXIONG, Inc. All rights reserved. ProPureX™