1. Angle grinder overview

Angle grinder is a common industrial cutting tool, widely used in construction sites, manufacturing, repair, paint spraying and other industries. This equipment is usually driven by an electric motor to drive a set of rotating grinding discs for cutting, polishing, grinding and other processing work. It is a very efficient and effective tool.

However, during use, the angle grinder without a protective cover brings certain safety hazards. This equipment will generate high-speed rotating cutting force and sparks when working. If these forces are not properly controlled, they may cause harm to the user and the surrounding environment.

2. Hazards of not installing a protective cover on the angle grinder

When using an angle grinder, there are safety hazards such as high-speed rotating grinding discs and ejected metal fragments. If the protective cover is not installed, it will cause serious harm to the operator's body, especially the eyes and facial tissues are most vulnerable to injury.

2.1. Hazards of broken objects: When the grinding wheel is processed, due to the very high speed, high-speed flying metal fragments or sand particles will be generated. These fragments and sand particles may fly out of the rotating grinding disc and enter the user's eyes, head and hands. These fragments will not only scratch the skin, but may also cause serious injuries such as blindness.

2.2. Hazards of abnormal operation: If there is no protective cover, the user may touch the grinding disc with fingers, palms and other parts, causing injuries to the hands or fingers, or improper operation may cause the tool to hit the grinding wheel, causing the tool to break or present an abnormal state.

3. Hazards of sight gaps: During the rotation of the grinding disc, if the user does not have a protective cover to block it, the grinding disc will cause damage to the surrounding cutting area, the operator's hands, body and even the head.

3. How to reduce the incidence of accidents

3.1. Install a protective cover

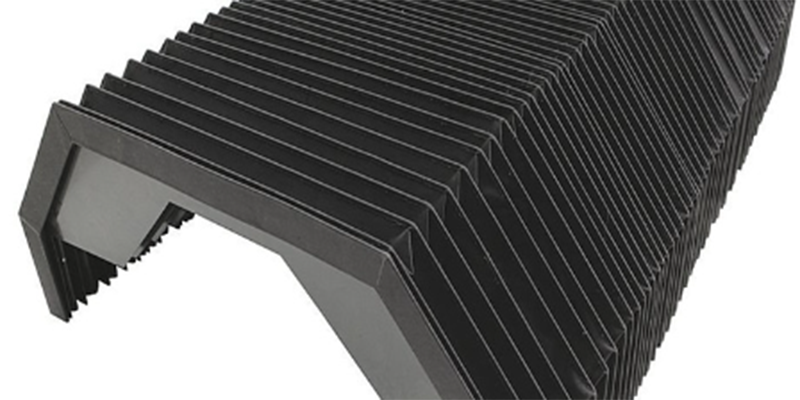

Installing a protective cover is the most basic and effective measure to avoid angle grinder accidents. Protective covers can be installed to prevent flying debris, sand, hands and fingers from the grinding disc from entering the space, detect abnormal conditions in time and protect the operator's body parts. Users must wear safety belts when using them, and ensure that the safety belts are not removed.

3.2. Check the grinding disc

Before use, the grinding disc must be checked for cracks, wear or other damage, etc. Grinding discs that do not meet the use standard requirements must be replaced immediately.

3.3. Use the right tools and equipment

When using tools and equipment with potential safety hazards, standard gloves, goggles, shoes and other safety equipment must be used, and the habit of maintaining safe production must be adhered to.

3.4. Adhere to personnel training

When operating an angle grinder, you must understand all the operations involved in the operation process, must undergo professional training, master various skills and precautions for using tools, and strictly follow the operating procedures to ensure the requirements of safe production.

In addition, safety education should be strengthened, employees' safety awareness should be enhanced, and safety skills should be improved, so as to effectively protect personal safety and the normal operation of equipment and prevent accidents caused by angle grinders without protective covers. In short, angle grinders without protective covers may cause great harm to the human body and its surrounding environment, and corresponding preventive measures must be taken to avoid safety incidents.

© 2012‐2022 SHANGHAI PUXIONG, Inc. All rights reserved. ProPureX™