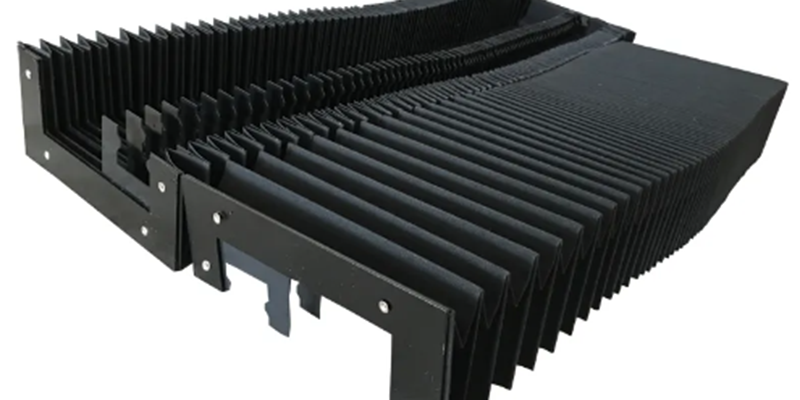

1. What is a machine tool protective cover?

The machine tool protective cover is used to protect the machine tool guide rails. It can protect the internal hard guide rails, linear guide rails and ball screws or transmission racks of the machine tool from corrosion and damage from the outside world. There are many types, including: accordion protective cover, steel plate protective cover, these two are used on the guide rails; and the screw protective cover used on the screw includes: round, square, polygonal, these types of methods are different, there are wire support type and stitching type. There are also rolling curtain protective covers and armor protective covers, etc.

2. Stability and service life of machine tool screw protection cover

The machine tool screw protection cover can be extended or compressed with the parts, and can be used vertically or horizontally. When used horizontally, it is recommended to use plastic or aluminum support rings to maintain a certain uniform distance between the inner cavity of the protection cover and the screw rod to extend the service life. When the stretching length is large, a metal ring can be added at each fold to improve the stability of the protection cover. It can effectively protect the screw, light bar, shaft, column and other parts from external pollution and damage such as dust. The steel ring support screw protection cover adopts a variety of fabrics, with a hard steel wire ring support inside, and can work normally between high temperature 110℃ and low temperature -40℃.

It can effectively prevent dust, water, oil, emulsion and chemicals, with a neat appearance and not easy to deform. Based on its strictness and firmness, this cover can also be used for ventilation and dust removal of many machines.

It can be extended or compressed with the parts, and can be used vertically or horizontally. When in horizontal position, use plastic or aluminum support rings to maintain a certain uniform distance between the inner cavity of the protection cover and the screw rod to extend the service life. When the stretching length is large, a metal ring is added to each compromise to improve the stability of the shield. Metal flanges are used for the connection or fixed end, or a sleeve type is selected.

The shield is flexible not only in material selection, but also in that it can determine the required diameter and length according to specific requirements. The sewn screw shield is sewn from stamped discs, and the two adjacent inner edges and two outer edges are sewn together. By sewing, a better shape stability and horizontal firmness can be achieved. The material can be selected from rubber attached cloth, oilproof cloth, waterproof cloth, flame retardant cloth, acid and alkali resistant cloth, asbestos cloth, and fireproof cloth according to different working environments.

© 2012‐2022 SHANGHAI PUXIONG, Inc. All rights reserved. ProPureX™