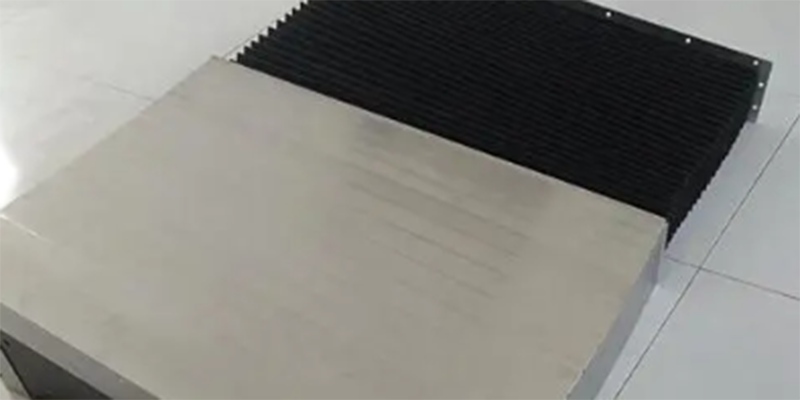

Armor shields are mainly used in machine tools and other mechanical equipment to protect internal components from damage by hot metal chips and other sharp objects. Each fold can withstand strong vibration without deformation. At the same time, it is applied to the bellows and remains in its original state at 900℃. They support each other and play a role in preventing small debris from penetrating.

The armor shield is designed to withstand strong vibrations and high temperatures up to 900°C while hindering the penetration of small debris. Its structure includes armor plates made of stainless steel or aluminum alloy sheets, which are mounted on the flaps of the shield and can be swung or fixed to adapt to different installation requirements and working conditions. The fixed armor can be applied to the shield: when the shield is in a compressed state, there is no obstacle so that these armors can maintain their original state. Due to the good adhesion between the preset armors, the shield has a reliable protective layer against a large amount of dust, sand, iron filings, etc.

In addition, the armor shield also has good high temperature resistance and flame retardant properties, which can effectively prevent dust, sand, iron filings and other debris from entering the machine tool, and protect the machine tool's guide rails, beams, columns and other components from damage. They are widely used in mechanical fields such as grinders, precision instruments, measuring instruments, CNC special machines, etc.

© 2012‐2022 SHANGHAI PUXIONG, Inc. All rights reserved. ProPureX™