1. What is a safety cover?

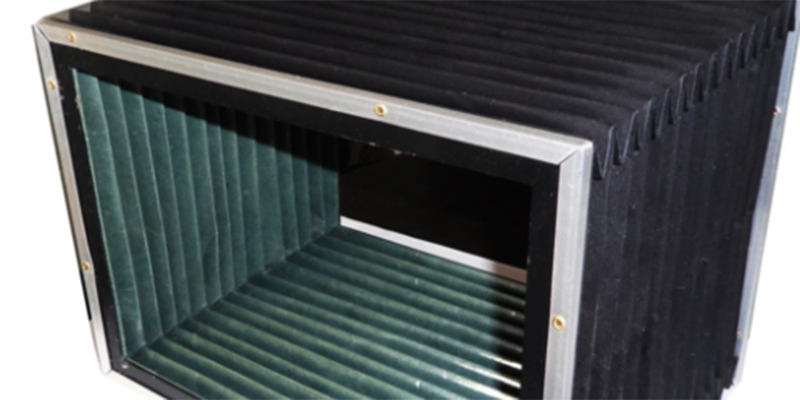

The cover can prevent dust, chips, hard sand, etc. from entering the track, reduce the damage of hard granular foreign matter to the sliding rail surface, reduce the influence of the guide rail deformation on the processing accuracy due to operation, and maintain the processing accuracy of the machine tool. The surface of the cover should be smooth without burrs and sharp edges, and should not become a new source of danger; and the cover should not affect the line of sight and normal operation, and should facilitate the inspection and maintenance of the equipment.

Safety shields refer to protective devices that effectively isolate various sources of danger that may cause harm to operators.

2. Hazard sources mainly include

1. Moving parts of mechanical equipment: By isolating people from the moving parts of the equipment, operators are prevented from directly contacting dangerous areas that may cause mechanical injuries.

2. Flying metal debris, harmful gases, and liquid splashes: Protective shields can be used to protect the face and neck from these flying dangerous substances.

3. High temperature phenomenon: In mechanical processing, especially for processing machine tools that use electrical, hydraulic, pneumatic and other principles to transmit power, the surface of the machine tool may generate high temperatures, and protective shields can effectively prevent workers from being burned by high temperatures.

4. Other dangerous parts: such as transmission belts, open gears, grinding wheels, electric saws, and other couplings, shafts, pulleys, and flywheels close to the ground, should be equipped with protective devices to isolate these dangerous parts.

In short, protective shields are a very useful protective device that has been widely used in various fields to protect human safety and health.

© 2012‐2022 SHANGHAI PUXIONG, Inc. All rights reserved. ProPureX™