Steel telescopic guide rail guards are the traditional form of protection for machine tools. They are widely used in this field, and play an effective protective role in preventing the entry of chips and other sharp objects. Through certain structural measures and suitable scraper plates, they can also effectively reduce the infiltration of coolant. Our steel telescopic guide rail guards can meet the ever-increasing requirements of modern machine tools for high technology, correct installation position, high operating speed, etc.

The standard structure is reasonably priced and suitable for most applications. The width can be up to 900mm. For larger widths, the edges must be folded to improve lateral stability. This can be achieved with the ridge type and the folded edges. In addition, the tilt type can effectively drain away liquids and debris. The number of sections of the steel telescopic guard is important for its proportion, weight and operating characteristics. Each single section should be as long as possible, so as to reduce the number of sections and reduce costs. In general, the maximum tension and minimum compression ratio should be between 3:1 and 5:1 (up to 10:1).

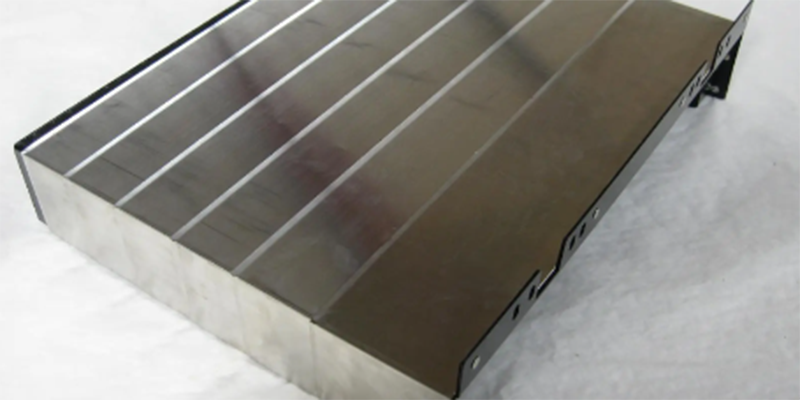

The steel telescopic guide guard is made of high-quality 2-3mm thick steel plate cold-formed, and can also be made of stainless steel on request. Special surface polishing will increase its value. The guard structure is also different according to the operating speed and guide rail. The guard with an operating speed of less than 10m/min is equipped with polyurethane or brass sliders. For medium speeds of less than 30m/min, we have rollers. In addition, a buffer system is required between the drive plate, the scraper plate and the suction plate. The purpose of the slider buffer system is to reduce collisions, noise and friction.

© 2012‐2022 SHANGHAI PUXIONG, Inc. All rights reserved. ProPureX™