PVC accordion-type protective cover group welding machine is a professional welding equipment, mainly used to produce accordion-type protective covers made of PVC. This kind of protective cover is widely used in various mechanical equipment, such as ordinary machine tools, CNC machine tools, hydraulic machinery, etc., to provide protection for machine tools and prevent guide rails, linear guides, ball screws or rotating racks from being corroded and damaged by the outside world.

2. Principle

PVC accordion-type protective cover group welding machine adopts high-frequency (high-frequency) plastic melting technology to weld PVC or TPU fiber coated cloth with PVC inner frame. During the welding process, the equipment generates heat at the contact surface of PVC or TPU coated cloth and PVC inner frame through the action of high-frequency electromagnetic field, so as to achieve the effect of melting and connecting. This welding method has high efficiency, good fastness, low maintenance rate and power saving.

3. Advantages

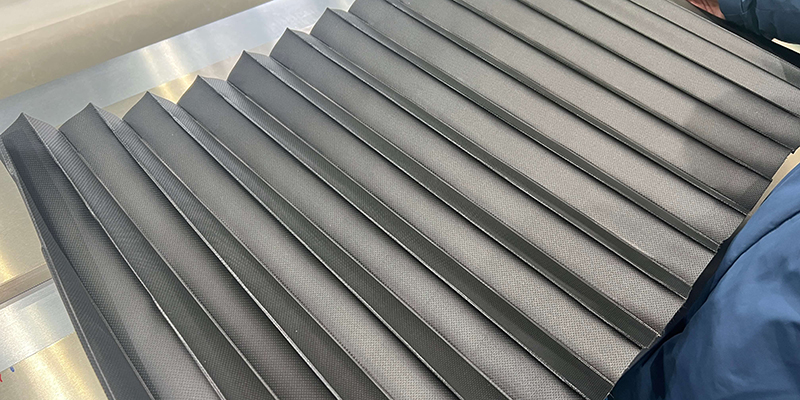

3.1. Tight and reasonable structure: The accordion-type protective cover produced by the PVC accordion-type protective cover group welding machine has a tight and reasonable structure, which can effectively protect the key components such as machine tool guide rails, linear guide rails and ball screws or rotating racks, and prevent them from being corroded and damaged by the outside world.

3.2. No noise: This equipment has low noise during operation, providing a quieter and more comfortable working environment for the staff.

3.3. Large stroke and fast movement: The accordion-type protective cover has a large stroke and a fast movement speed, which can meet the needs of various mechanical equipment under different working conditions.

3.4. Long service life: Due to the use of high-quality materials and advanced production technology, the accordion-type protective cover has a long service life and can provide long-term protection for mechanical equipment.

3.5. Oil-resistant, water-resistant and corrosion-resistant: PVC material has good oil-resistant, water-resistant and corrosion-resistant properties, can resist the erosion of various liquids and corrosive substances, and protect internal equipment from damage.

3.6. Good sealing: The accordion-type protective cover has excellent sealing performance, which can effectively prevent dust, dirt and other impurities from entering the interior of mechanical equipment, keeping the equipment clean and operating normally.

3.7. Beautiful and generous: The accordion-type protective cover has a beautiful appearance, smooth surface and regular shape, which adds infinite color to the overall shape of the machine tool and also enhances the overall value of the machine tool.

IV. Application

Mechanical equipment protection: The protective cover produced by the PVC accordion-type protective cover group welding machine is mainly used to protect the machine tool guide rails, linear guide rails and ball screws or rotating racks to prevent them from being corroded and damaged by the outside world. This protective cover is widely used in various mechanical equipment, such as ordinary machine tools, CNC machine tools, hydraulic machinery, etc. Automobile industry: Flexible accordion-type protective covers are also increasingly widely used on lifting platforms of automobile production assembly lines. This type of protective cover can meet the requirements of height and smooth operation, providing effective protection for automobile production lines. Other fields: In addition, PVC accordion-type protective covers are also widely used in the fields of medicine, measurement, automatic control and food technology. These industries have high requirements for protective covers, which need to be dustproof and non-toxic to food. PVC accordion-type protective covers just meet these needs and provide reliable protection for these industries. In short, the PVC accordion-type protective cover group welding machine is a powerful and widely used equipment that provides effective protection for various mechanical equipment and production lines. With the continuous advancement of technology and the increase in market demand, its application prospects will be broader.

© 2012‐2022 SHANGHAI PUXIONG, Inc. All rights reserved. ProPureX™