The batch heat-sealing method of protective covers mainly uses heat-sealing technology, which is a connection technology that heats two or more materials to the melting point through a heat source to make them melt and combine with each other. The following is an introduction and principle of the batch heat-sealing method of protective covers:

1. Introduction

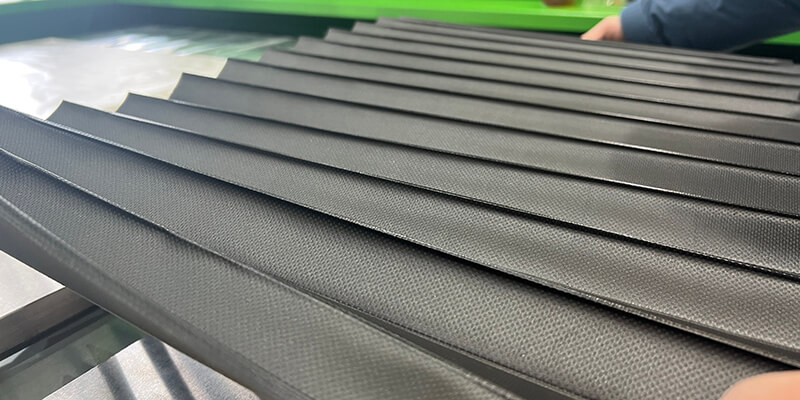

Batch heat-sealing technology is usually used for mass production of protective covers, such as accordion-type protective covers. Through heat-sealing equipment, multiple protective covers can be processed at the same time, which greatly improves production efficiency. In the heat-sealing process, different heat-sealing methods and materials can be selected as needed to meet the performance requirements of different protective covers.

2. Principle

1. Hot-melt welding: This is a commonly used heat-sealing method. In the hot-melt welding process, the material of the protective cover is heated to the melting point by a heat source (such as a hot air gun, hot plate, etc.) to melt and bond with each other. This method is suitable for materials with similar chemical properties, similar melting points and thermoplasticity.

2. Ultrasonic welding: Ultrasonic welding uses ultrasonic vibration to generate friction heat to achieve heat sealing. During welding, ultrasonic vibration is transmitted to the protective cover material, causing it to generate heat by rapid friction, and then the material melts and bonds with each other. This method is usually suitable for welding thin materials.

3. Heat-sealing bonding: Heat-sealing bonding is a method of bonding two materials together through a hot adhesive. During welding, the adhesive is heated to the melting point by a heat source, turning it into a liquid state and bonding the two materials together. This method is suitable for connections between different types of materials, and the welded connection points have high strength and sealing.

In the batch heat-sealing process of protective covers, it is necessary to select appropriate heat-sealing methods and parameter settings according to specific material, structure and performance requirements. At the same time, in order to ensure the heat-sealing quality and production efficiency, the heat-sealing equipment also needs to be regularly maintained and serviced.

© 2012‐2022 SHANGHAI PUXIONG, Inc. All rights reserved. ProPureX™