1). Heat-sealing welding process

The heat-sealing welding process of high-end accordion-type protective covers mainly includes the following steps:

1. Material preparation: Select suitable PVC materials to ensure that the quality, thickness and color of the materials meet the requirements of the protective cover.

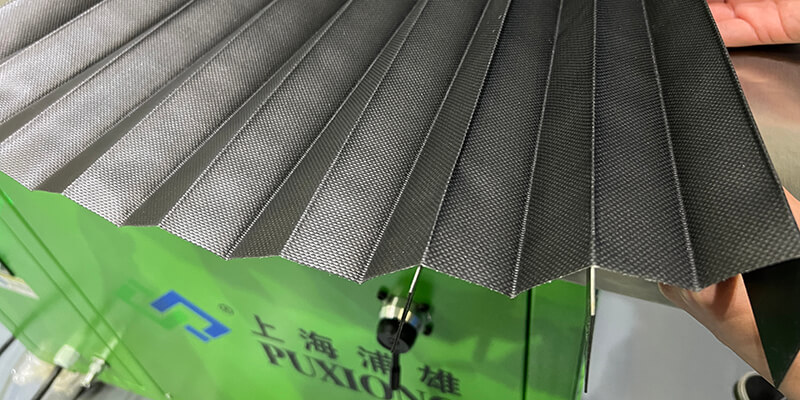

2. Design and production: According to the shape, size and actual needs of the protective cover, the PVC material is cut into corresponding shapes and sizes, and made into an accordion-type folding structure.

3. Heat-sealing welding: Use professional heat-sealing welding equipment to heat-seal and weld the various parts of the PVC material. During the heat-sealing welding process, it is necessary to control parameters such as temperature, time and pressure to ensure the welding quality.

4. Quality inspection: Perform quality inspection on the welded protective cover, including appearance inspection, size measurement, strength test, etc., to ensure that the protective cover meets the quality requirements.

2). Heat-sealing welding principle

The heat-sealing welding principle is to use the property of thermoplastics that can melt at high temperatures. After heating two or more pieces of plastic materials to a certain temperature, they are melted and bonded together by pressure. In the production process of high-end accordion protective covers, heat welding technology can firmly bond the internal frame of the PVC material and the external folding together to form a whole.

© 2012‐2022 SHANGHAI PUXIONG, Inc. All rights reserved. ProPureX™