notes on extended 1.5m protective cover

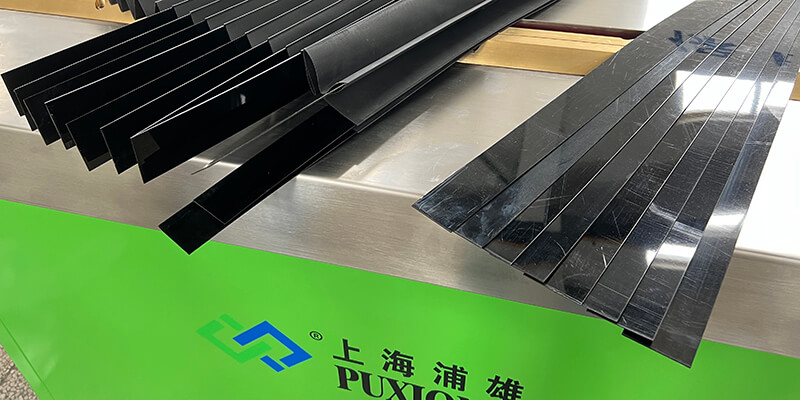

1. Material selection: Choose the appropriate material according to the purpose and working environment of the protective cover. For plastic protective covers, plastic materials such as PVC, PU, TPU, EVA, etc. are usually selected, while for metal protective covers, stainless steel and carbon steel are common choices.

2. Design considerations: Since the length of the protective cover reaches 1.5 meters, its strength and stability need to be considered during design. Reasonable structural design and the use of reinforcing ribs can effectively enhance the bearing capacity and impact resistance of the protective cover.

3. High-frequency heat sealing equipment: Select suitable high-frequency heat sealing equipment to ensure that the equipment can provide sufficient power and stability to meet the heat sealing needs of the 1.5-meter-long protective cover.

4. Operation technology: High-frequency heat sealing operations require professional technicians. Operators need to master the operation methods and skills of high-frequency heat sealing equipment to ensure the quality and efficiency of welding or welding.

5. Quality control: During the high-frequency heat sealing process, the quality of welding or welding needs to be strictly controlled. By regularly checking indicators such as the appearance, size and strength of the weld, ensure that the quality and performance of the protective cover meet the requirements.

6. Subsequent processing: After high-frequency heat sealing is completed, the protective cover may need to be processed, such as grinding, polishing, spraying, etc., to improve its appearance quality and corrosion resistance.

It should be noted that although high-frequency heat sealing technology has many advantages, it also has some limitations and challenges in practical applications. For example, the heat sealing performance and welding requirements of different materials may be different, and appropriate materials and equipment need to be selected according to the specific situation. In addition, harmful gases and noise pollution may be generated during high-frequency heat sealing, and corresponding environmental protection measures need to be taken to reduce the impact on the environment and operators.

© 2012‐2022 SHANGHAI PUXIONG, Inc. All rights reserved. ProPureX™