On the grand stage of industrial manufacturing, machine tools resemble virtuoso dancers, transforming raw materials into exquisite industrial products through precise movements and efficient operations. Standing as loyal guardians beside these performers are machine tool protective covers, which erect an impregnable defense for core components with their exceptional waterproof performance through silent vigilance.

1.1 Dual Role of Coolant

During operation, machine tools endure complex and ever-changing environments. In many machining scenarios, coolant serves as an indispensable "cooling agent." Functioning as a thermal regulator, it effectively reduces heat generated by high-speed cutting between tools and workpieces, preventing accelerated tool wear and workpiece deformation caused by overheating.

1.2 Invisible Hazard

While performing its vital functions, coolant simultaneously poses a latent threat to core components. Leaks or splashes can easily penetrate critical areas like electrical systems and transmission mechanisms. For electrical systems, moisture acts as a destructive force - compromising circuit insulation, triggering short circuits and electrical leakage, and potentially causing component burnout that paralyzes machinery. In transmission systems, prolonged coolant exposure accelerates corrosion and wear on lead screws and guide rails, degrading transmission accuracy and undermining machining quality and operational stability.

2.1 Structural Ingenuity

The prominence of machine tool protective covers stems from their meticulously engineered design and premium material selection.

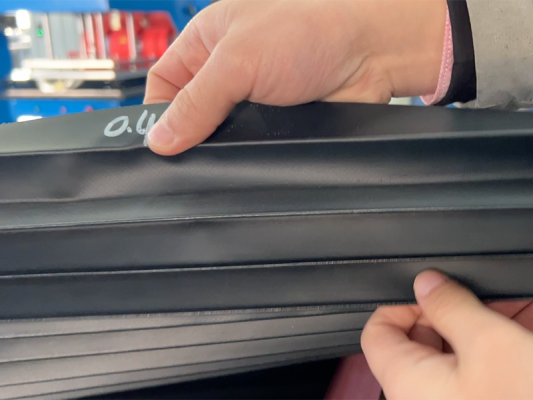

In structural design, these covers employ advanced sealing technologies. Critical joints feature specialized treatments such as rubber gasket reinforcement or precision-engineered seamless interfaces to prevent coolant infiltration. Adjustable splash guards at access points dynamically adapt to machine operation modes and coolant spray directions, creating an effective liquid barrier.

2.2 Material Innovation

Protective covers utilize materials optimized for waterproofing and corrosion resistance. Stainless steel variants demonstrate superior liquid protection while resisting chemical erosion from coolants, maintaining structural integrity over prolonged use. High-performance polymers are increasingly adopted for their lightweight flexibility and excellent sealing properties, adapting effortlessly to diverse operational demands.

This dual innovation in architecture and material science transforms protective covers into more than mere barriers - they become intelligent safeguarding systems that harmonize with industrial processes while maintaining relentless protection.

© 2012‐2022 SHANGHAI PUXIONG, Inc. All rights reserved. ProPureX™