As an innovative product in the field of modern industrial equipment protection, the bellows-type protective cover delivers efficient and reliable protective solutions for high-precision equipment such as CNC machine tools and automated production lines. This is achieved through its unique foldable structural design, high-performance material applications, and modular customization capabilities. Below is an analysis from two dimensions: core advantages and technological breakthroughs.

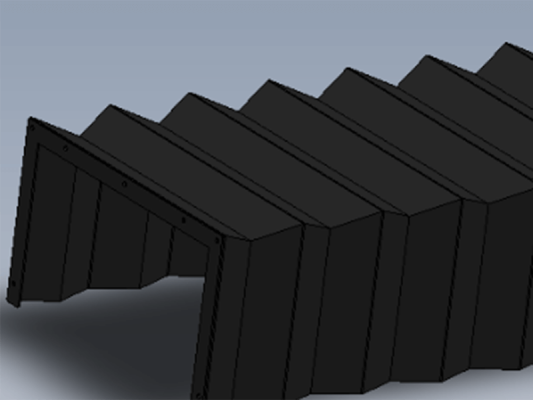

1. Bellows-Style Folding Mechanism

Utilizing a multi-section corrugated structure with PVC frames or high-strength nylon fabric, the cover achieves free expansion and contraction, with a compression ratio reaching 1:10. For example, in CNC machine tool guideway protection, the cover expands or retracts in real time with tool movement, maintaining close contact with equipment surfaces. This eliminates the limitations of traditional rigid covers, such as restricted travel distance and susceptibility to jamming.

2. Three-Dimensional Space Adaptability

The cover supports horizontal, vertical, and inclined installations to meet complex operational demands. In automotive welding production lines, for instance, the bellows cover flexibly deforms with the six-axis motion of robotic arms while maintaining sealing integrity even under ±90° bending conditions. This effectively blocks welding slag and coolant splashes.

3. Modular Splicing Technology

With single-section lengths up to 2,000 mm, the cover allows infinite splicing via quick-connect components. A heavy equipment manufacturer adopting this technology reduced the installation cycle of a large gantry milling machine’s protective system by 60% and lowered maintenance costs by 45%.

1. Composite Material System

The outer layer employs flame-retardant PVC-coated fabric (temperature resistance: -30°C to +120°C), reinforced with galvanized steel skeletons for impact resistance, and a flame-retardant sponge interlayer for silent buffering. Tests confirm that this structure withstands 10J energy impacts without deformation and achieves a UL94 V-0 fire resistance rating.

2. Precision Manufacturing Processes

High-frequency welding technology ensures integrated molding of frames and fabric, with weld seam strength exceeding 85% of the base material. A precision electronics company using this process improved the cover’s airtightness to 0.1 mbar·L/s, successfully achieving IP67 certification.

3. Self-Cleaning Surface Treatment

A nano hydrophobic coating (contact angle >150°) enables automatic shedding of oil residues and metal debris. In construction machinery testing, maintenance cycles for the cover extended from twice weekly to once monthly, boosting production efficiency by 30%.

© 2012‐2022 SHANGHAI PUXIONG, Inc. All rights reserved. ProPureX™