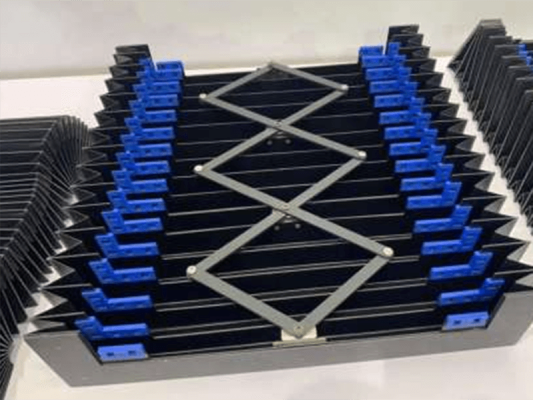

The lead screw protective cover, an essential component in industrial automation, plays a vital role in safeguarding lead screws—the core elements of motion control systems—from environmental damage, ensuring stable equipment operation and extending service life.

Lead screws, as precision transmission components, are responsible for torque transfer and positional accuracy in industrial automation equipment. However, harsh operational environments expose them to contaminants like dust, oil, water, and debris, leading to reduced precision, accelerated wear, and even mechanical failure. Protective covers mitigate these risks by forming a physical barrier against pollutants while allowing unrestricted screw movement.

Lead screw protective covers are widely used in:

By improving equipment reliability, reducing maintenance costs and downtime, they deliver significant economic benefits to manufacturers.

© 2012‐2022 SHANGHAI PUXIONG, Inc. All rights reserved. ProPureX™